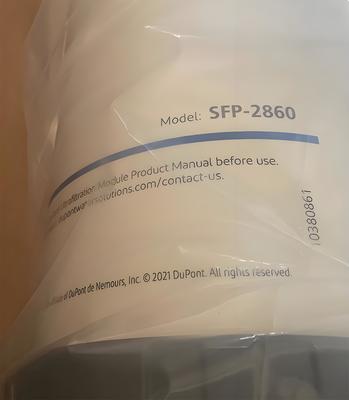

DuPont SFP-2860 UF Membrane: Advanced Pretreatment Solution for Pretreatment for RO Systems

Dettagli:

| Luogo di origine: | Cina |

| Marca: | DuPont |

| Certificazione: | CE |

| Numero di modello: | SFP-2860 |

| Documento: | UF-IntegraTec-P-Series-PVDF...en.pdf |

Termini di pagamento e spedizione:

| Quantità di ordine minimo: | 1 PC |

|---|---|

| Prezzo: | negoziabile |

| Imballaggi particolari: | imballaggio di esportazione standard |

| Tempi di consegna: | 5-8 giorni di lavoro |

| Capacità di alimentazione: | 60000 unità al mese |

|

Informazioni dettagliate |

|||

| SFP-2860Membrane Area: | 51 m² (549 ft²) | SFP-2860 Range di flusso (25 ° C): | 40–90 LMH |

|---|---|---|---|

| SFP-2860 MAX TMP: | 2.1 bar | Portata SFP-2860: | 2,0–6,9 m³/ora |

| SFP-2860 Peso (vuoto): | 48 kg | Applicazioni: | Pretrattamento per i sistemi RO |

| Evidenziare: | DuPont SFP-2860 UF membrane,UF membrane for RO pretreatment,DOW UF membrane with warranty |

||

Descrizione di prodotto

Product Overview

DuPont SFP-2860 ultrafiltration membrane delivers superior water treatment performance with its advanced hollow fiber technology. Designed for industrial applications, this membrane provides excellent removal efficiency for turbidity, bacteria, and viruses while maintaining high flux rates. Its robust construction ensures reliable operation in challenging water conditions with strong chemical resistance. Ideal for reverse osmosis pretreatment, wastewater reuse, and process water purification, the SFP-2860 offers low energy consumption, reduced maintenance requirements, and extended service life. The system features easy scalability for various capacity needs and simplified maintenance procedures.

![]()

- Precision Filtration: 0.03 μm nominal pore size removes bacteria, viruses, colloids, and particulates to protect downstream RO systems.

- Engineered Durability: Hydrophilic PVDF fibers offer superior mechanical strength and chemical resistance (pH 2-11) for extended service life.

- Space-Saving Design: Shorter length (1,860 mm / 73.2 in) ideal for low-ceiling installations with 51 m² (549 ft²) effective membrane area.

- Broad Compatibility: Processes surface water, seawater, industrial wastewater, and municipal effluents.

| Attribute | Value |

|---|---|

| Membrane Area | 51 m² (549 ft²) |

| Flux Range (25°C) | 40–90 LMH |

| Max TMP | 2.1 bar |

| Flow Rate | 2.0–6.9 m³/hr |

| Weight (Empty) | 48kg |

| Target Applications | Industrial wastewater reuse, Seawater pretreatment for desalination, Compact containerized plants, Cooling tower blowdown recovery |

| Parameter | SI Units | US Units |

|---|---|---|

| Filtrate Flux @ 25ºC | 40-120 l/m2/hr | 24-70 gfd |

| Flow range | 2.0 - 6.1 m3/hr | 9.2 - 26.7 gpm |

| Temperature | 1-40ºC | 34-104ºF |

| Max. inlet module pressure (@ 20ºC) | 6.25 bar | 93.75 psi |

| Max. operating TMP | 2.1 bar | 30 psi |

| Max operating air scour flow | 12 nm3/hr | 7.1 scfm |

| Max backwash pressure | 2.5 bar | 36 psi |

| Operating pH | 2-11 | |

- Filtrate turbidity ≤0.1 NTU

- Filtrate SDI ≤2.5

Proper start-up of a UF system is indispensable for preparing the membranes for operational service and preventing membrane damage. Adhering to the correct start-up sequence also contributes to ensuring that the operating parameters of the system conform to the design specifications.

Before commencing the system start-up procedures, membrane pretreatment, installation of the membrane modules, instrument calibration, and other system checks should be accomplished. Kindly refer to the product technical manual.