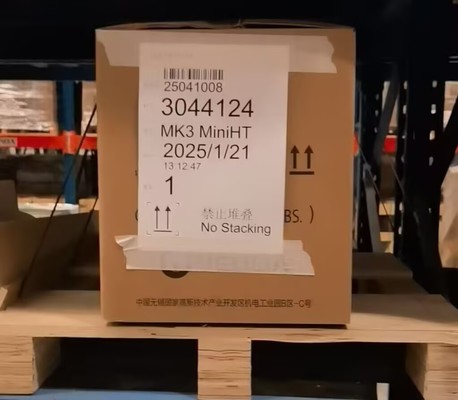

Veolia E-Cell MK-3 Mini HT EDI module for pharmaceutical ultrapure water production

Dettagli:

| Luogo di origine: | Cina |

| Marca: | VEOLIA |

| Certificazione: | CE |

| Numero di modello: | Veolia Edi MK-3Miniht |

| Documento: | FSpwE-CellMK-3MiniHT_EN.pdf |

Termini di pagamento e spedizione:

| Quantità di ordine minimo: | 1 PC |

|---|---|

| Prezzo: | negoziabile |

| Imballaggi particolari: | imballaggio di esportazione standard |

| Tempi di consegna: | 1 mese |

| Termini di pagamento: | T/t |

| Capacità di alimentazione: | 60000 unità al mese |

|

Informazioni dettagliate |

|||

| Intervallo di portata miniht: | 0,5–1,6 m3 /h (2,2–7,0 gpm) | Peso di spedizione del prodotto miniht: | 57 kg (126 libbre) |

|---|---|---|---|

| Dimensioni miniht di questo modello (larghezza x altezza x profondità): | 30 cm x 61 cm x 29 cm | Resistività miniht: | ≥ 10 (farmaceutico) o ≥ 16 MOHM-CM (industriale |

| Prodotto sodio: | ≤ 3 ppb (industriale) | Temperatura massima di igiene del prodotto: | 85ºC (185ºF) |

| Pressione di ingresso di igiene massima del prodotto: | 2,1 bar (30 psi) | Applicazione del prodotto: | Acqua farmaceutica e purificata in laboratorio conforme a USP ed EP |

| Evidenziare: | Veolia E-Cell MK-3 EDI module,pharmaceutical ultrapure water EDI,mini HT EDI module |

||

Descrizione di prodotto

Il modulo di elettrodeionizzazione (EDI) Veolia E-Cell MK-3 Mini HT è stato progettato per la lucidatura del permeabile per osmosi inversa (RO) per produrre acqua ultra pura.Fornisce acqua di alta purezza (risistenza fino a 10 MΩ·cm)Ideale per la generazione di energia, i semiconduttori, la microelettronica e i prodotti farmaceutici, questo modulo compatto (30x61x28 cm) offre un funzionamento continuo.elevati tassi di recupero (78-93%), e capacità di disinfestazione dell'acqua calda

| Intervallo del flusso | 0.5·1.6 m3/h (2.2·7.0 gpm) |

| Peso di spedizione | 57 kg (126 lb) |

| Dimensioni | 30 cm x 61 cm x 29 cm |

| Resistenza | ≥ 10 MOhm-cm (farmaceutici) o ≥ 16 MOhm-cm (industriali) |

| Temperatura massima di disinfestazione | 85oC (185oF) |

- Tecnologia HT-EDITM brevettata per la produzione di acqua di grado reagente

- Consumo energetico inferiore del 90% rispetto ai sistemi a letto misto

- Funzionamento senza manutenzione con sistema di controllo intelligente

- Monitoraggio in tempo reale della conduttività, del pH e della caduta di pressione

- Disegno brevettato del canale di flusso a scaglie impedisce la scalabilità

Mantiene una resistività superiore a 18,2 MΩ*cm con una riduzione energetica del 22% rispetto alle apparecchiature EDI tradizionali.

- Unità di base - Purificazione autonoma

- RO-EDI integrato - Slitta di depurazione completa

- Versione GMP - con supporto completo per la convalida

- Marcatura CE, RoHS, CSA ed EAC

- Materiali conformi alla FDA

- Certificato UKCA

- Prodotto in strutture ISO 9001 e ISO 14001

- Halal certificato da IFANCA®

| Parametro | Valore |

|---|---|

| Pressione di ingresso | 60,9 bar (100 psi) |

| Temperatura massima | 40°C (104°F) |

| Diminuzione della pressione | 10,4-2,8 bar (20-40 psi) |

| Tasso di recupero | Fino al 93% |

| Conducibilità | < 117 μS/cm |

| Intervallo di pH | 4-11 |

Ideale per l'acqua per iniezioni, l'acqua purificata farmaceutica e i sistemi di acqua purificata di laboratorio.

FG Water Technologies è un'entità ad alta tecnologia specializzata nella progettazione, produzione e spedizione internazionale di attrezzature per il trattamento dell'acqua.,cibo e bevande, prodotti chimici e energia.